How Modular Extensions Solve the Biggest Homeowner Pain Point

Why living on a building site for months is no longer necessary—and what the alternative actually looks like.

The Modular Advantage

80% of construction happens in a factory, not at your home. Your extension is built while you continue living normally.

On-site time: 2-4 weeks compared to 3-6 months for traditional builds. That’s 80% less disruption.

Better quality through consistency. Factory conditions mean no weather delays, systematic inspections, and precision that site work can’t match.

Not every project suits modular—but for many homeowners, it solves the disruption problem almost entirely.

This is the question behind the question when homeowners research extensions. They ask about costs and timescales, but what they really want to know is: how much disruption am I signing up for? How long will my home not feel like my home?

What Traditional Construction Actually Involves

Before explaining how modular construction differs, it’s worth being honest about what happens during a conventional on-site build. This isn’t intended to frighten you—it’s simply honest about what thousands of homeowners experience every year.

The Dust Problem

Construction creates dust. Lots of it. Cement dust, plaster dust, brick dust, wood dust. It infiltrates rooms that are supposedly sealed off. It gets into soft furnishings, into electronics, into every surface in your home. One homeowner described it as “horrible cement dust that gets everywhere” and that feeling of perpetually cleaning without ever catching up.

Most builders make efforts to contain dust with sheeting and sealed doorways. These measures help, but they don’t eliminate the problem. You’ll be hoovering more frequently than you thought possible, and still finding dust in unexpected places months after the build completes.

The Timeline Problem

The construction industry has a well-documented problem with project delivery. According to the Federation of Master Builders, 61% of construction firms have been affected by skilled labour shortages, leading to job delays for 49% and outright cancellations for 23%. When your extension is delayed, you live on a building site for longer than planned.

Weather is another factor entirely outside anyone’s control. Rain stops foundation work. Frost affects concrete curing. Wind makes certain tasks unsafe. A build that starts in autumn can extend well into the new year as the British weather takes its toll.

The Life Disruption Problem

Beyond the physical mess, there’s the disruption to daily life. Builders arriving at 8am, sometimes earlier. Loss of access to parts of your home. Temporary loss of utilities while connections are made. The inability to relax in your own space because there are always strangers present.

- If you work from home, the noise makes concentration difficult

- If you have young children, managing their safety around a construction site adds stress

- If you have pets, keeping them away from dangerous materials becomes a constant concern

Some families move out during major builds. This solves the daily inconvenience but adds significant cost for temporary accommodation, plus the disruption of living elsewhere for months.

How Modular Construction Changes This Picture

Modular construction doesn’t eliminate all disruption. But it fundamentally changes when and where that disruption occurs. Moving construction work off-site transforms the homeowner experience.

The Factory Environment

In a modular system, approximately 80% of the construction work happens in a factory rather than at your home. The walls, roof, windows, insulation, electrical rough-in, and much of the finishing work are completed in controlled conditions before anything arrives at your property.

This factory work happens while your home continues to function normally. You go about your daily life, largely unaware that your extension is being built somewhere else. The dust, noise, and disruption that would fill your home for months instead occurs in a purpose-built manufacturing facility where it belongs.

The On-Site Phase

When the modular components arrive at your property, the on-site work happens in days rather than months. Foundation preparation may take a week. The module installation itself often takes just one to three days. Connection to services and final finishing might add another week or two.

Compare this to a traditional build where groundwork, brickwork, roofing, windows, electrical, plumbing, plastering, and finishing all happen sequentially on your property over three to six months. The modular approach compresses the invasive on-site phase to a fraction of that time.

Quality Through Consistency

Factory construction brings manufacturing discipline to building work. According to McKinsey’s analysis of modular construction, factory-built modules can reduce construction schedules by 20-50% while improving quality through better-controlled conditions and consistent processes.

- Weather doesn’t affect factory production

- Skilled workers operate in optimised conditions with proper tooling and lighting

- Quality checks happen at every stage before the product leaves the factory

- The result is a more consistent finished product with fewer defects to fix later

Traditional vs Modular: Direct Comparison

This table shows how traditional and modular construction approaches compare across the factors that matter most to homeowners.

| Factor | Traditional Build | Modular Build |

|---|---|---|

| On-site duration | 3-6 months typically | 2-4 weeks typically ✓ |

| Dust and debris | Significant, ongoing throughout build | Minimal, mainly during foundation work ✓ |

| Weather impact | High: rain, frost, wind cause delays | Low: factory work unaffected ✓ |

| Noise disruption | Daily for duration of build | Concentrated in short period ✓ |

| Tradespeople on site | Many different trades over months | Focused team for short period ✓ |

| Quality control | Variable, depends on conditions | Factory-controlled with inspection ✓ |

| Timeline certainty | Lower: many variables cause delays | Higher: factory schedule predictable ✓ |

What the Modular Process Actually Looks Like

Understanding the stages of a modular project helps set realistic expectations. Here’s what happens from initial enquiry to completion.

Design and Planning

We visit your property, discuss requirements, and develop designs. Planning applications follow the same process as any other extension. Your home is completely unaffected—no construction happening yet.

Factory Manufacturing

Your extension is built in a factory environment while you continue living normally at home. No builders, no dust, no disruption whatsoever during this phase.

Site Preparation

Excavation for foundations, laying the base, preparing service connections. This is the noisiest phase, but it’s measured in days, not months. Yes, there will be a digger in your garden.

Module Installation

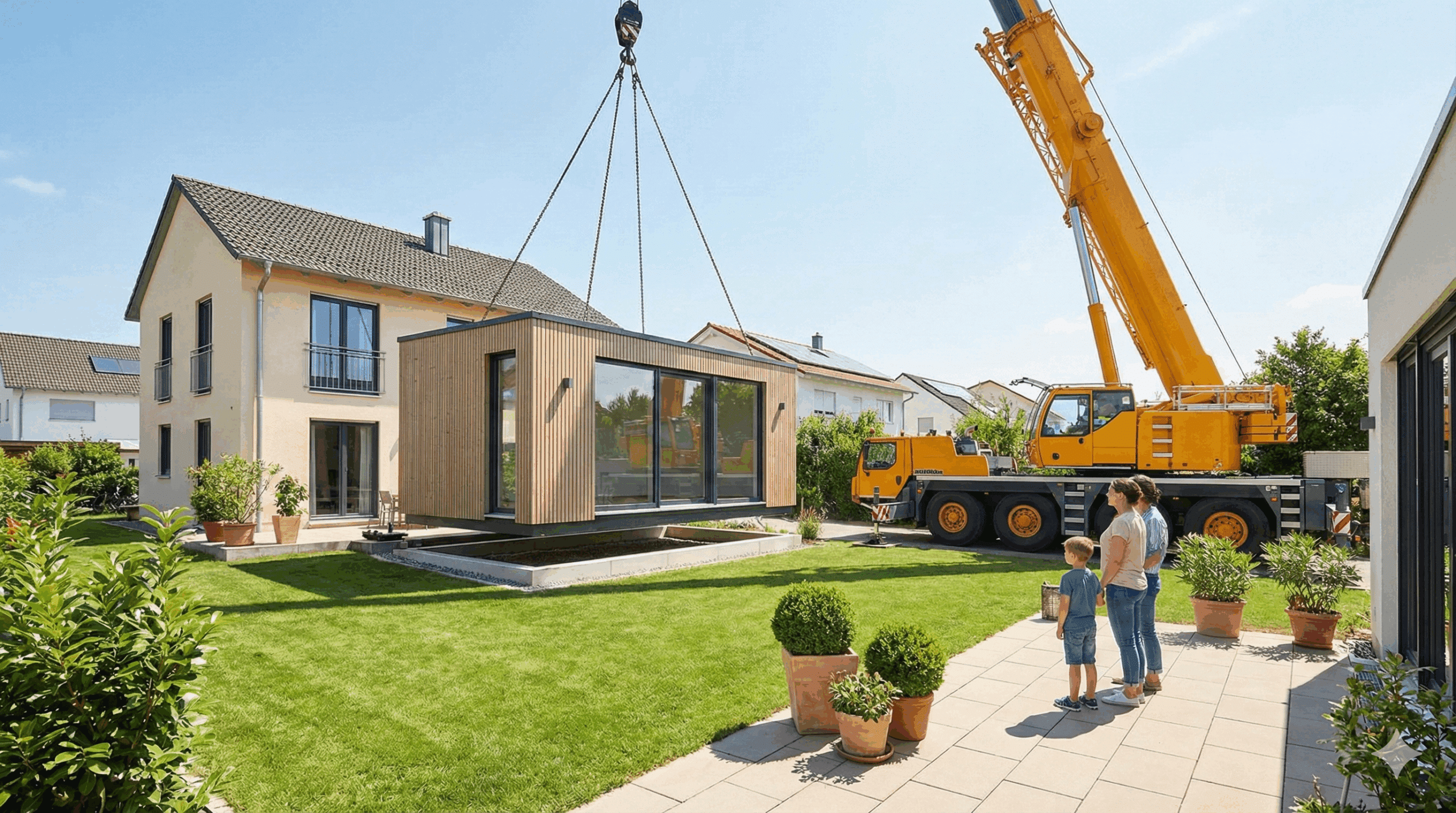

The manufactured module arrives and is craned into position. The structure arrives substantially complete—windows installed, insulation in place, internal finishes largely done.

Connection and Finishing

Connecting services, making the junction between module and existing home, completing remaining finishing work. Tradespeople on site for part of each day.

The Bottom Line on Timing

Total on-site disruption from start of groundwork to completion: typically 3-4 weeks.

Compare this to 3-6 months for a traditionally built extension of similar size. The modular approach compresses the invasive on-site phase to a fraction of that time.

When Modular Is Not the Right Answer

We believe in honest advice. Modular construction is not the best solution for every project. Here are situations where traditional construction may be more appropriate.

⚠️ Consider Traditional Construction If…

Complex or irregular sites: Modular requires crane access. Properties with very limited access, significant level changes, or obstructions that prevent crane operation may not be suitable.

Highly customised designs: Modular works best with designs that fit factory production. Highly unusual shapes or one-off architectural features that change during construction are harder to deliver through modular.

Listed buildings and sensitive heritage: Extensions to listed buildings often require traditional materials and methods to satisfy conservation requirements. The process may need to demonstrate traditional craft skills.

Modular Extensions Across Surrey and the South East

For homeowners across Surrey and the surrounding areas, modular construction offers particular advantages. Property values in this region justify investment in quality extensions. Busy professional households often cannot tolerate months of living on a building site. And the desire to minimise disruption to neighbours in close-proximity housing makes shorter on-site phases especially attractive.

The region also has good road access for module delivery, making logistics straightforward for most properties. We have installed modular extensions throughout Surrey, from suburban family homes to rural properties and town centre locations.

Our modular glass extension system delivers the thermal performance and design quality you would expect from a bespoke build, with the speed and reduced disruption of factory production.

Making the Right Choice for Your Situation

The disruption of home extension construction is a genuine concern, not an irrational fear. Living on a building site is stressful, messy, and exhausting. Knowing that modular construction can reduce this disruption by 80% or more is valuable information when deciding how to add space to your home.

But reduced disruption is not the only factor. Design requirements, site constraints, budget, and timeline all play a role. The right construction method is the one that best balances all these factors for your specific situation.

Ready to Explore Modular?

If minimising disruption is a high priority for you, our modular glass extension system offers a proven solution. We’d be happy to discuss whether it’s the right fit for your project.

Contact us to arrange an initial consultation about your extension project.

Frequently Asked Questions

How much less disruption is there really?

The on-site phase of a modular build is typically 2-4 weeks compared to 3-6 months for a traditional build. That’s around 80% less time with builders on your property. Because most construction happens in a factory, you avoid the ongoing dust, noise, and intrusion of traditional builds.

Does faster mean lower quality?

No. Factory construction typically produces higher and more consistent quality than site construction. Components are manufactured in controlled conditions with proper tooling, consistent temperatures, and systematic quality checks. Weather doesn’t affect the work, and the same skilled workers follow optimised processes repeatedly.

Is modular construction more expensive?

Modular extensions are generally comparable in cost to traditionally built extensions of similar specification. Manufacturing efficiency offsets logistics costs. Where modular often saves money is in hidden costs: less need for temporary accommodation, reduced time off work, and fewer overruns.

Can I still have a bespoke design?

Modular systems offer significant design flexibility within their parameters. You can choose dimensions, configurations, glazing types, finishes, and features. However, if your design requires genuinely one-off architectural elements that cannot be standardised, traditional construction may offer more latitude.

What happens if something goes wrong in manufacture?

Problems identified in the factory are resolved in the factory, before anything arrives at your property. Defects are caught during quality control rather than discovered during installation. If a component doesn’t meet standards, it’s rejected and corrected before shipping.

Do I need planning permission for a modular extension?

Planning requirements are the same for modular and traditional construction. Whether you need permission depends on the size, position, and nature of your extension, not on how it’s constructed. Some extensions fall within permitted development rights; others require full planning applications.

How is the extension transported to my property?

Manufactured modules are transported by road on flatbed lorries. The delivery route is surveyed in advance to ensure access is possible. At your property, a crane lifts the module from the lorry and positions it on the prepared foundation. The process typically takes a few hours.

What if my property has limited access?

We assess access during our initial site survey. Most properties can accommodate modular delivery, but some cannot. Factors include road width, turning circles, overhead obstructions, and crane positioning. If access is marginal, we explore solutions. If modular genuinely isn’t feasible, we’ll tell you honestly.

Will there still be any dust or mess?

Some, yes. Foundation work creates excavation spoil. The junction between your existing house and the new extension requires some internal work. But the volume and duration of mess is dramatically reduced compared to traditional construction. Most messy work happens in the factory.

How long does the whole process take?

Total project timeline is typically 16-24 weeks from initial enquiry to completion. This breaks down as: design and planning (8-12 weeks), factory manufacturing (4-8 weeks), and on-site work (2-4 weeks). The on-site phase is short, but overall expect 4-6 months including design and permissions.

Are modular extensions thermally efficient?

Yes, and often better than site-built. Factory construction allows precise installation of insulation without the gaps and thermal bridges that can occur in site construction. Our systems are designed to meet or exceed Building Regulations for thermal performance, with U-values that ensure year-round comfort.

What warranty comes with a modular extension?

Our modular extensions come with manufacturer warranties on components and workmanship. We also offer insurance-backed guarantees that provide protection even if something happened to our company. Full warranty details are provided during the quotation process.

Can I watch my extension being built?

Yes, factory visits can be arranged. Many clients find it reassuring to see their extension taking shape in controlled conditions before it arrives at their home. We can schedule a visit during the manufacturing phase so you can see the quality of work and progress being made.

What if I want to change something during manufacture?

Changes during manufacture are possible but may affect timeline and cost. The design is finalised before manufacturing begins precisely to avoid variations that plague traditional construction. If you do need changes, we discuss implications and find the best path forward. Early-stage changes are easier than late-stage ones.

Ready to Add Space Without the Chaos?

Our modular glass extensions deliver quality and comfort with minimal disruption. We work across Surrey, Sussex, Hampshire and the South East.